Orange Butter Lip Balm

This...

We get a lot of questions about curing soap. The typical thought of our callers is that soap is dangerous until it has cured for 3 to 6 weeks. This is dangerous thinking! Soap is a fantastic chemical reaction between a fat and an alkali. The resulting product is a synergy of these two items, fat + alkali = soap. In times long ago many items were cleaned with fats. Can you imagine cleaning with fats and oils? Most likely you can’t. We all know how harsh some modern chemical cleaners are, and we often wear gloves when using these types of products. Soap is a wonderful blend which is greater than either of its components, the synergy that sparks our interest and excites our minds.

We get a lot of questions about curing soap. The typical thought of our callers is that soap is dangerous until it has cured for 3 to 6 weeks. This is dangerous thinking! Soap is a fantastic chemical reaction between a fat and an alkali. The resulting product is a synergy of these two items, fat + alkali = soap. In times long ago many items were cleaned with fats. Can you imagine cleaning with fats and oils? Most likely you can’t. We all know how harsh some modern chemical cleaners are, and we often wear gloves when using these types of products. Soap is a wonderful blend which is greater than either of its components, the synergy that sparks our interest and excites our minds.

So, how does one tell when their soap is cured and why is curing needed if the soap is not dangerous? First, it is important to understand the phase we call cure time or curing. This length of time is location and weather dependent. Curing is used to have each bar of soap come to an equilibrium of how much water the soap retains, a balance between soap and atmosphere. Curing is to allow each soap to dry to the fullest extent allowed in each location so the resulting bar can last as long as possible. When using soap that is 24 hours old we know the soap quickly reduces in size because too much soap is being used at each washing, the soap is dissolving too quickly and going right down the drain. Keeping a cured soap dry between uses is important. So, curing is essentially dehydrating. Because we are not adding any other means than maybe a fan in a room with good air circulation we don’t think of this as a mechanical means of dehydrating, but drying is nonetheless what is happening. How does one tell the soap has cured? Easy! Use your scale!

A scale is the most valuable tool we use in making soap. Some would argue that they could never give up their immersion blenders but I will argue that there is nothing to blend until the weight of the oils and fats is known. I’m not the most excited person when thinking of hand stirring a large batch of soap, but I certainly will draw the line that my scale is my most valued lab tool.

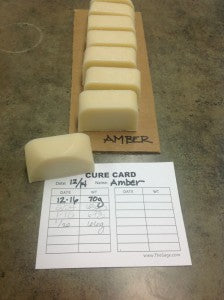

So… how do we do this? CURE CARDS to the rescue! We printed a quick reference card to help you with your record keeping. Each pad has 50 sheets of of CURE CARDS, peel one off and use with each batch you are curing. Write the name of the batch and date it was made. Then stack your cut bars to dry. Pin the card down with the lead bar in each curing stack. Weigh that lead soap every few days and record the date and weight. When your soap stops losing weight then your soap is fully cured! These card packs are now in our catalog and can be had for free through our Free Gifts and Teas program. Isn’t this great? I am really excited to share my no-fail method of knowing when a soap is cured. Once your soap has cured, keep this CURE CARD in your records so you will know how long the batch has cured before being wrapped for sale. You do keep records, don’t you?

This...